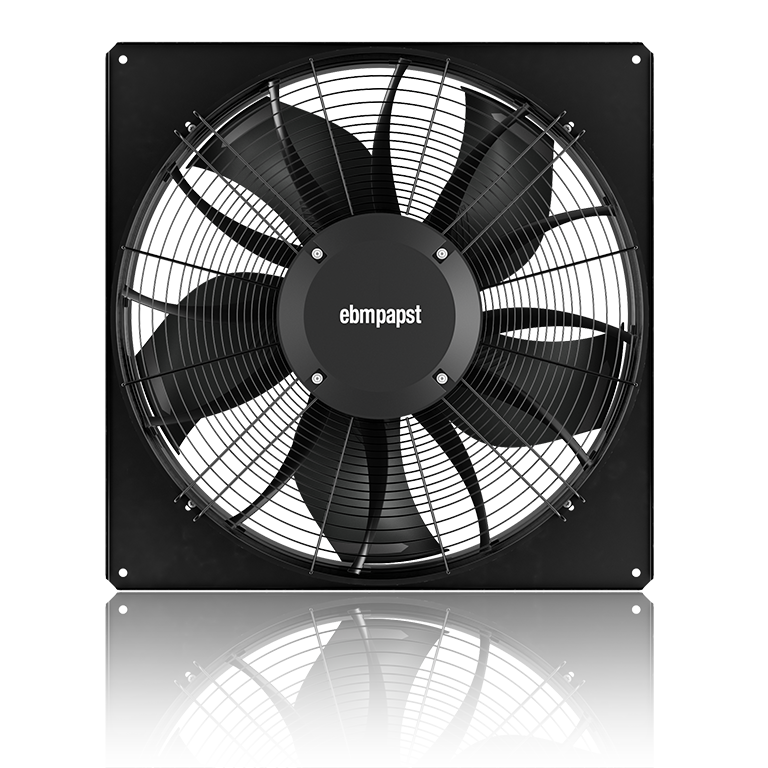

Future-proof with ebm‑papst

The minimum requirements for fan efficiency which have been stipulated in the Ecodesign Directive since 2009 are once again being tightened in 2026. The overall system consisting of the rotor, motor, and stator is measured, and if these components are purchased from different providers, the equipment manufacturer itself has to provide proof of EC conformity.

Save on time-consuming measurements and unnecessary paperwork! As a leading manufacturer, ebm‑papst offers complete fans from a single source – to be installed right away in your application. We therefore assume responsibility for the correctness of the efficiency information and also provide you with the required EC declaration of conformity.